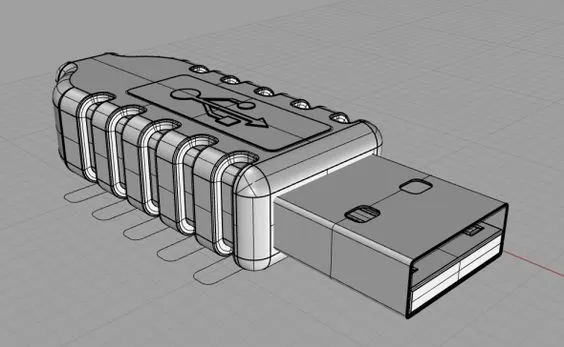

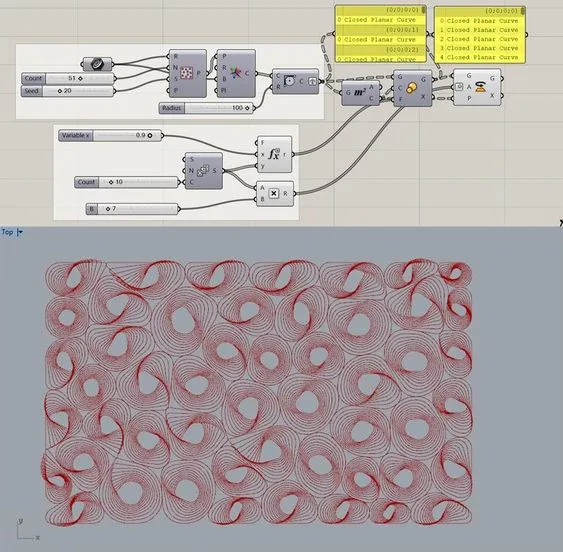

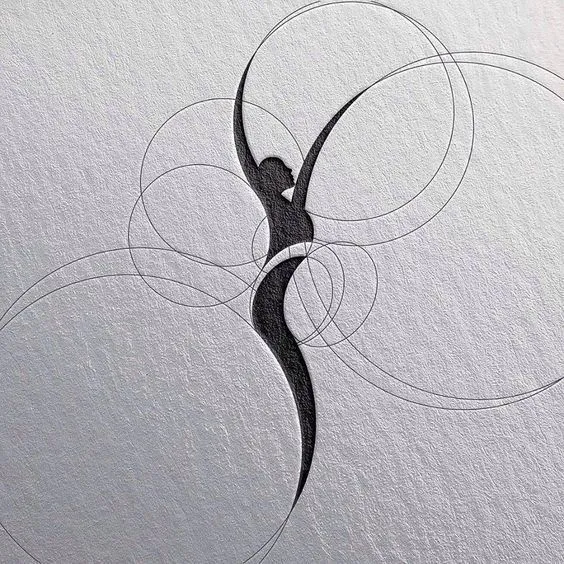

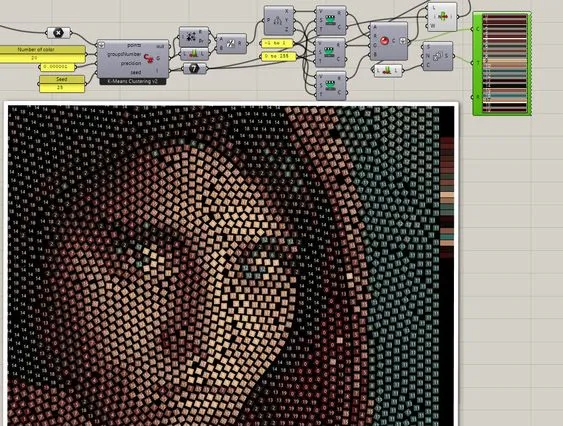

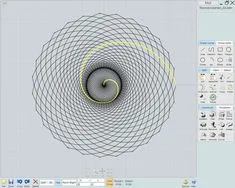

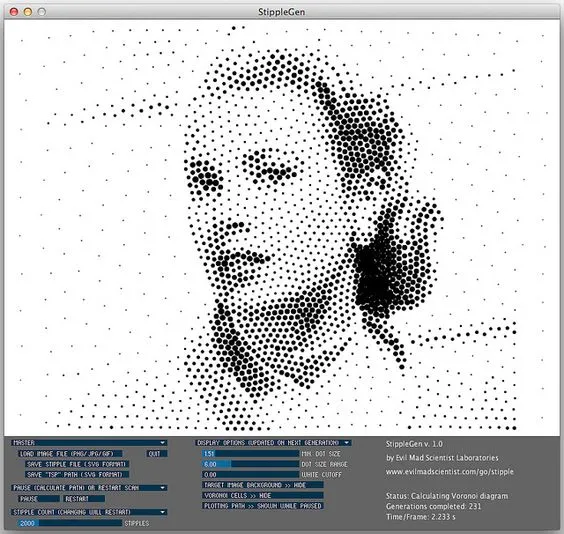

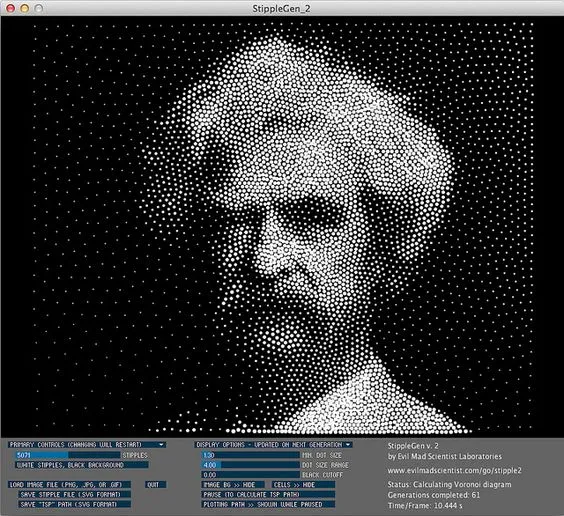

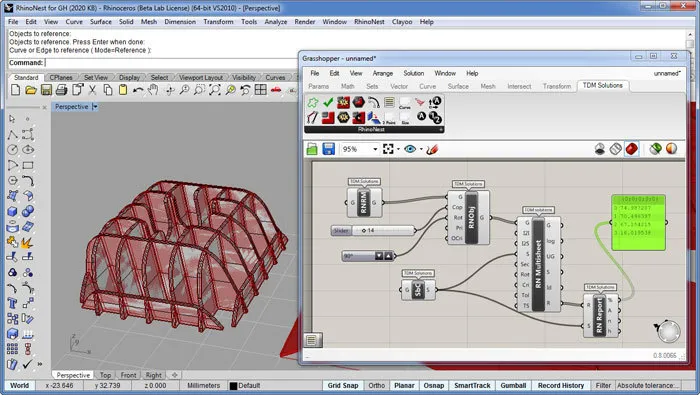

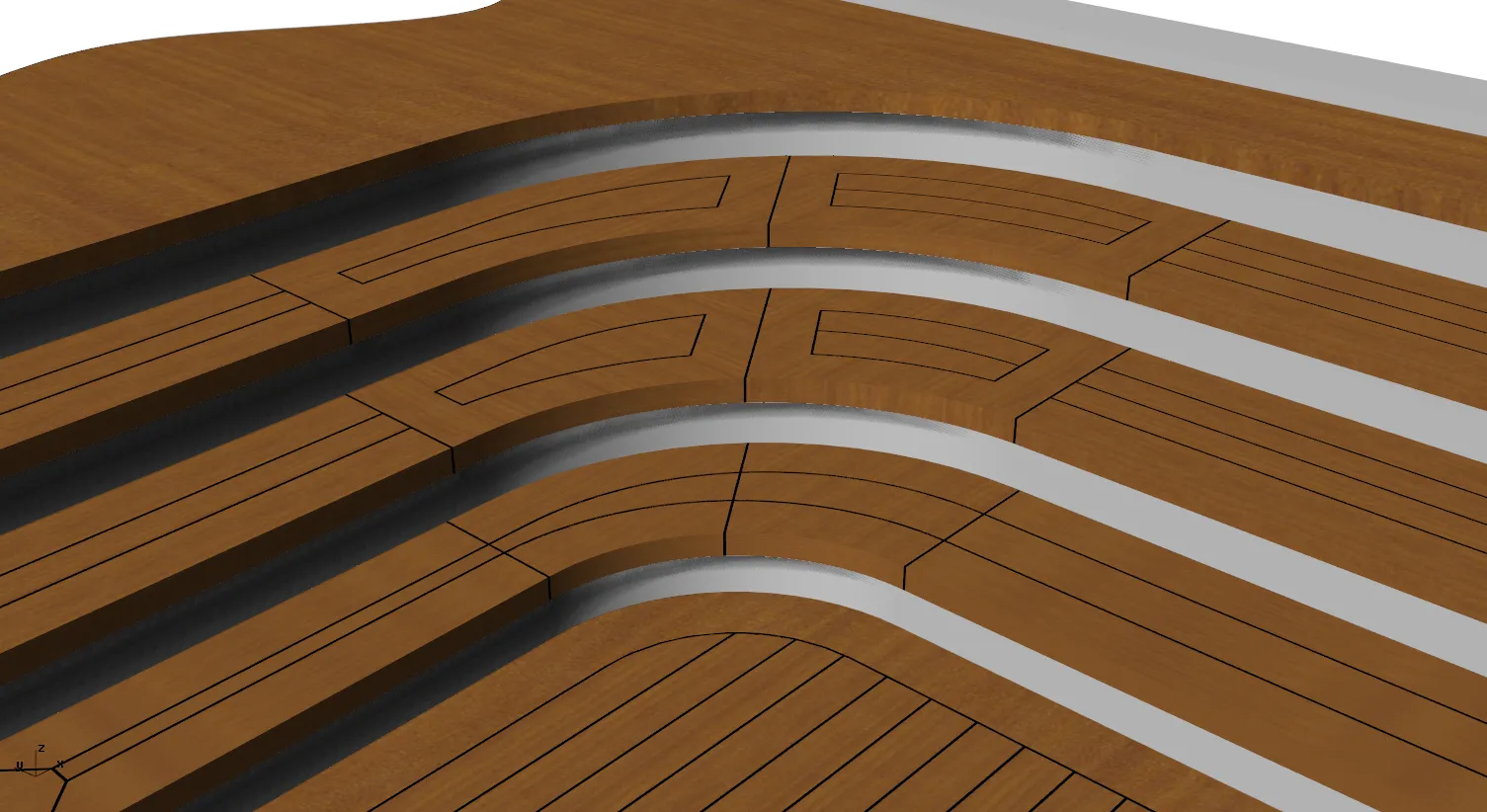

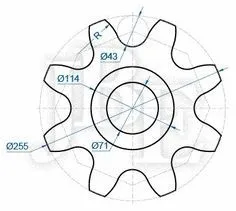

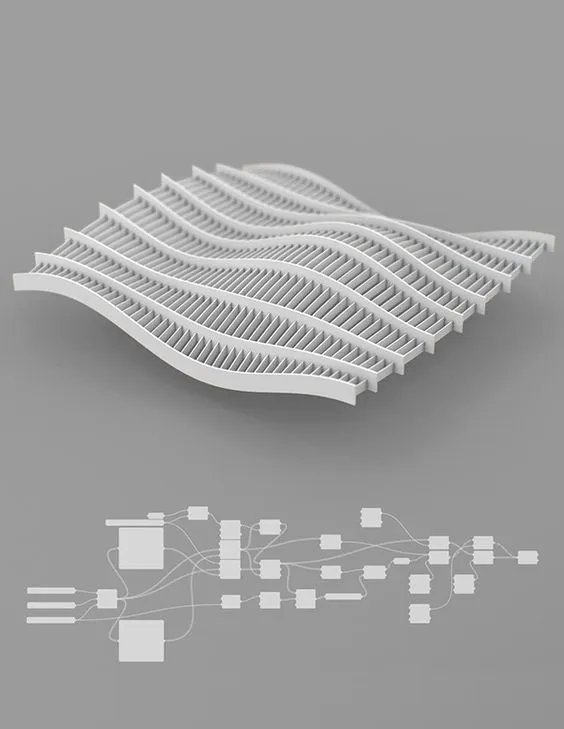

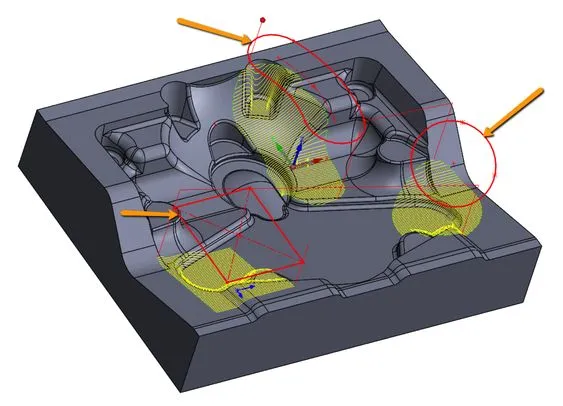

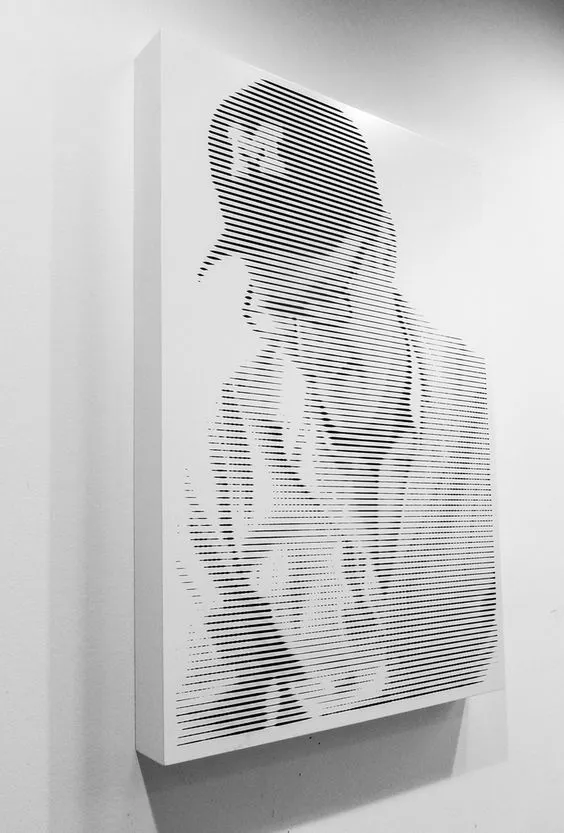

📌 Phase A: 📐 CAD (Computer Aided Design)

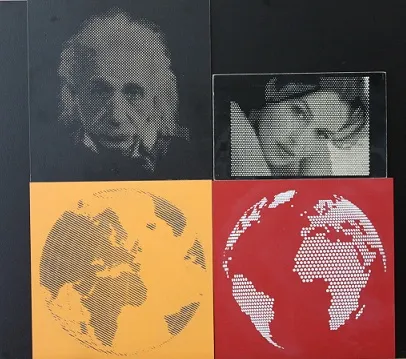

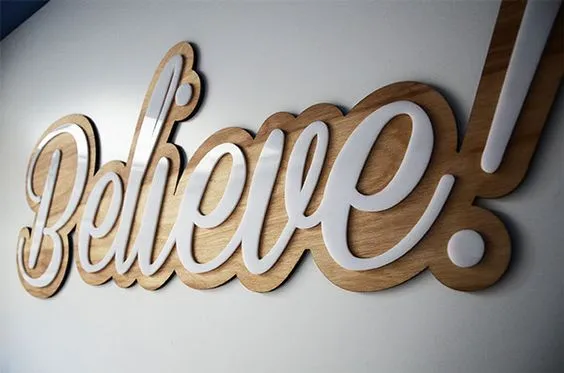

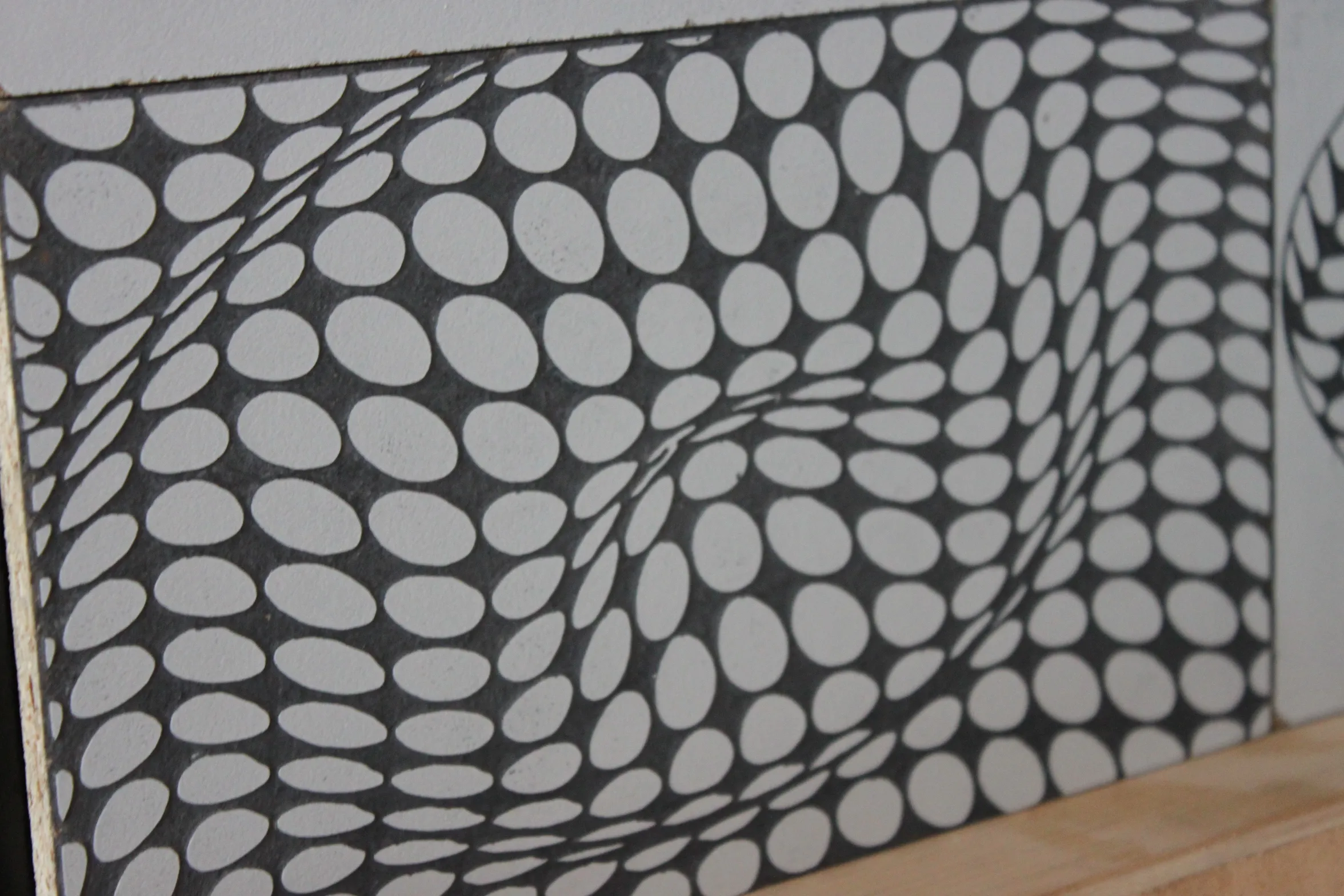

This phase forms the foundation of every CNC project. Leveraging the most advanced and powerful tools available today, our team is able to create high-quality designs — including mechanical ones — even from hand-drawn sketches. Techniques such as Parametric design , Halftone or Marquetry etc, represent some of the key strengths of our design expertise.

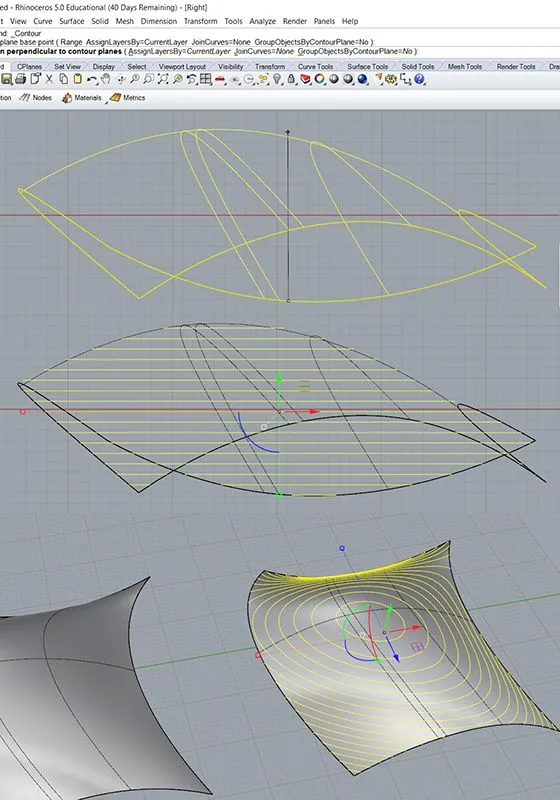

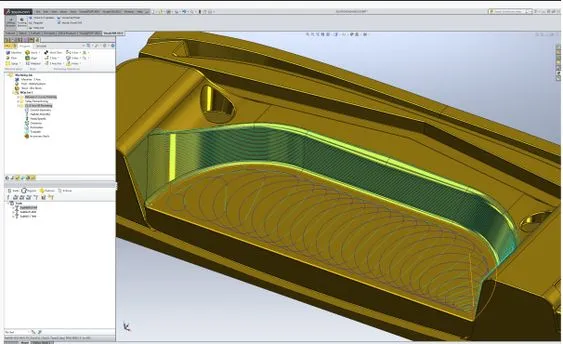

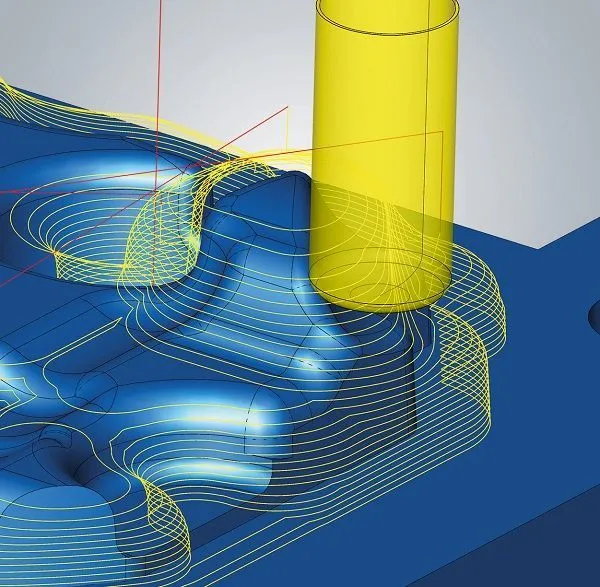

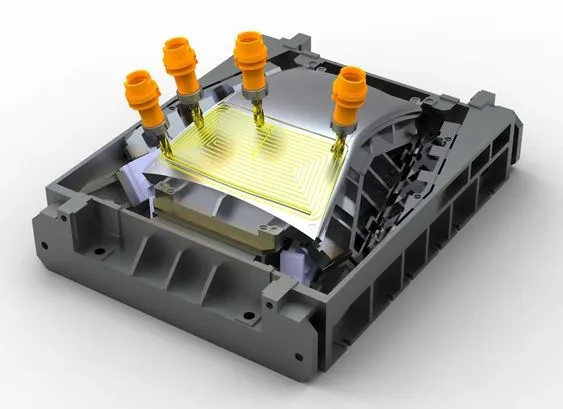

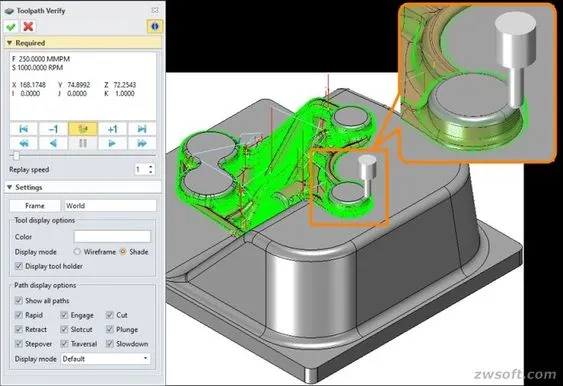

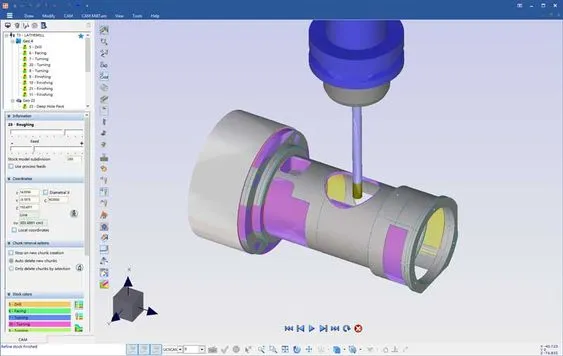

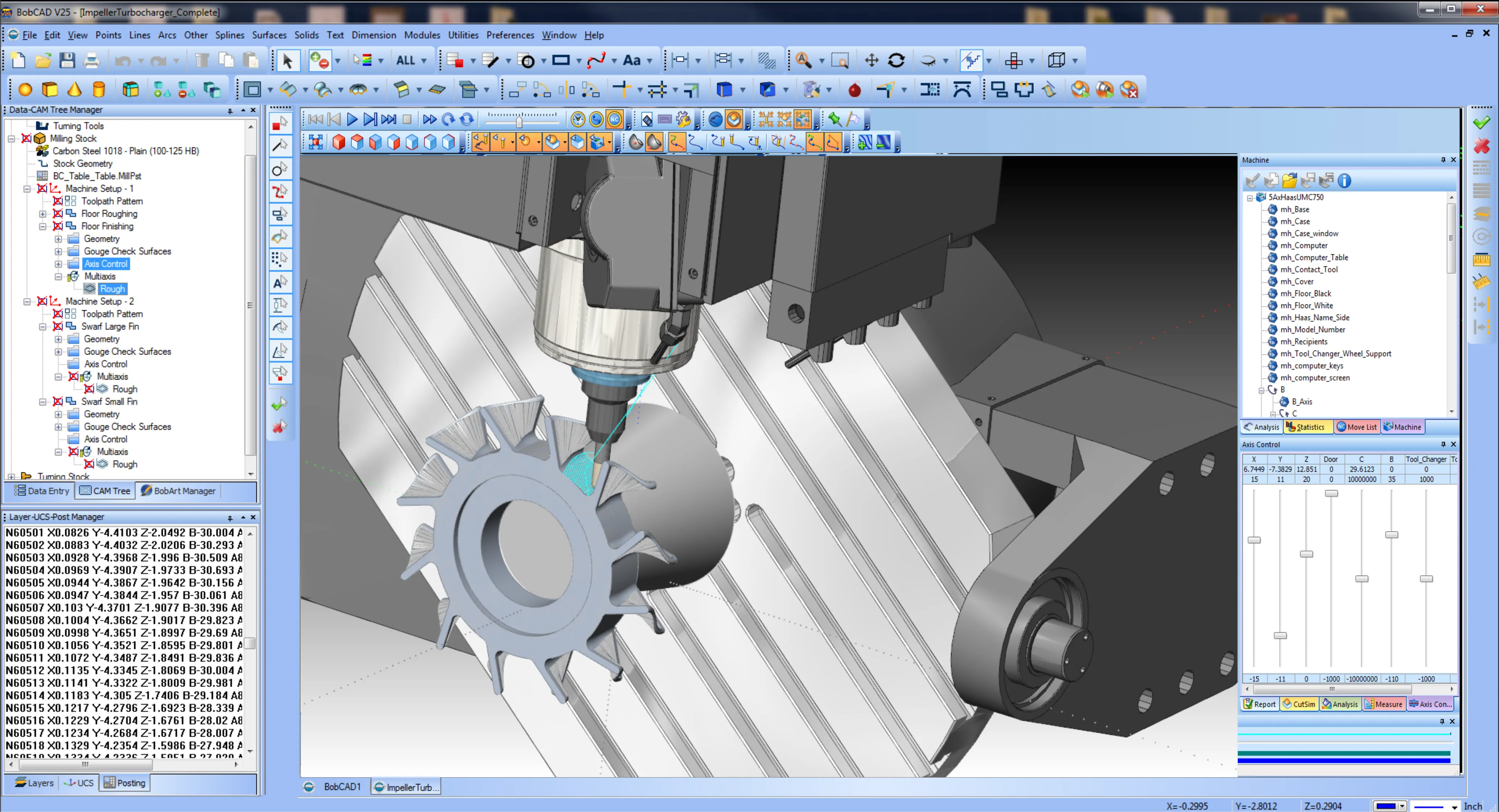

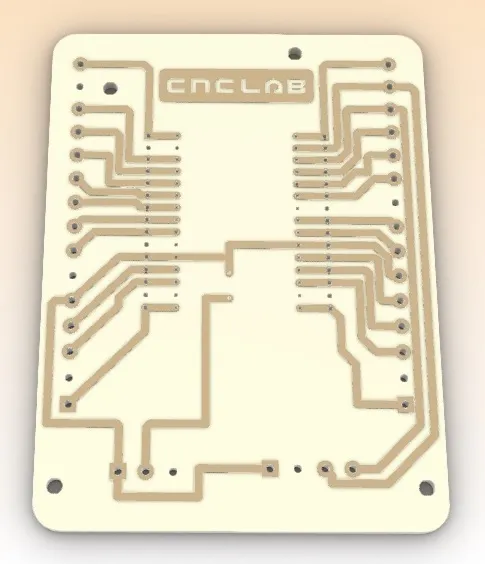

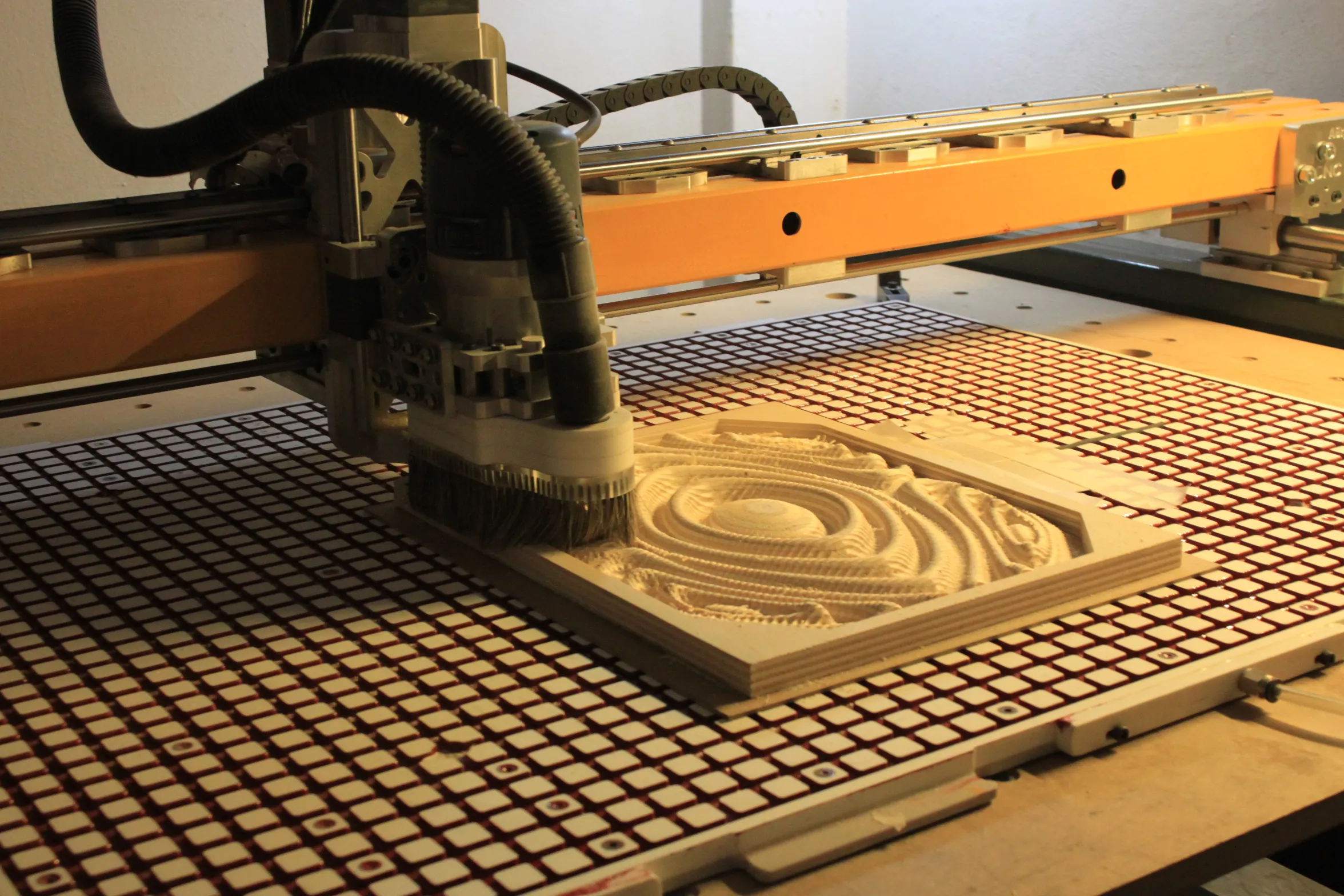

📌 Phase B: 🛠️ CAM (Computer Aided Manufacturing)

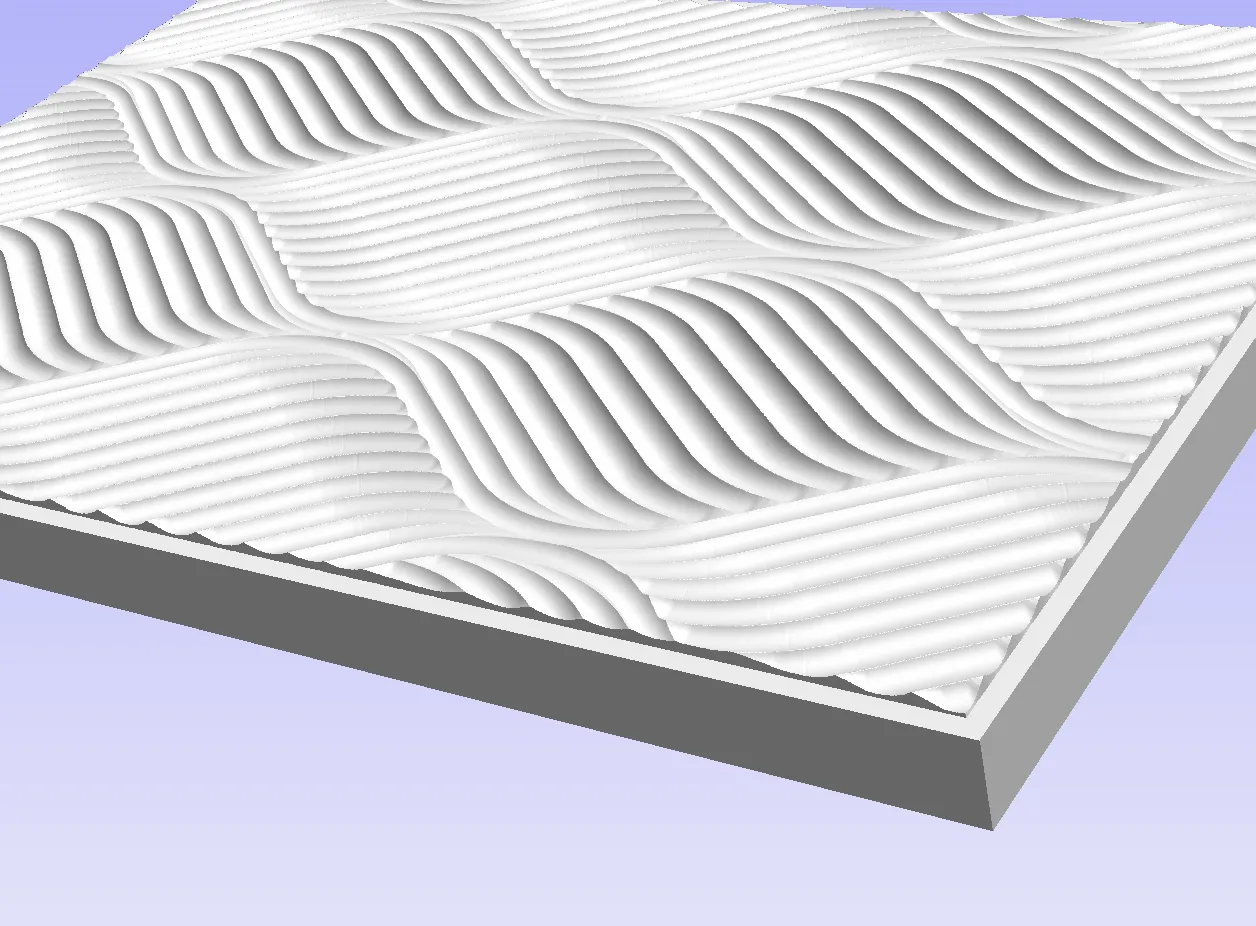

The CAM process is driven by the finalized design. At this stage, the material is chosen along with its appropriate dimensions (stock material).

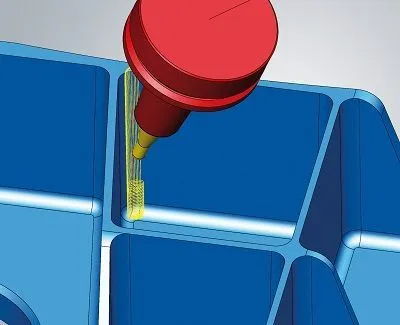

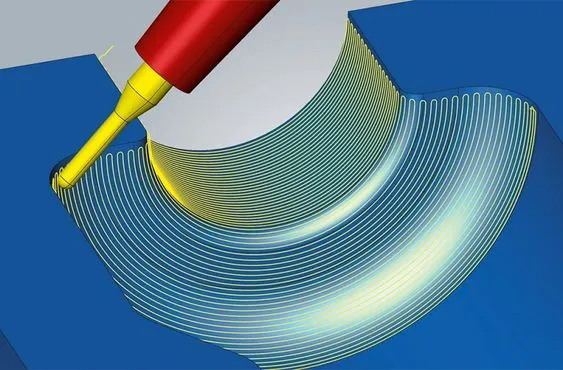

Based on the geometry of the part and the machine's available movement axes, the path for the cutting tool —

toolpath — is defined.

Once this process is complete, the toolpaths are translated into machine-readable code —

gcode — which the control system uses to guide the machine's motors.

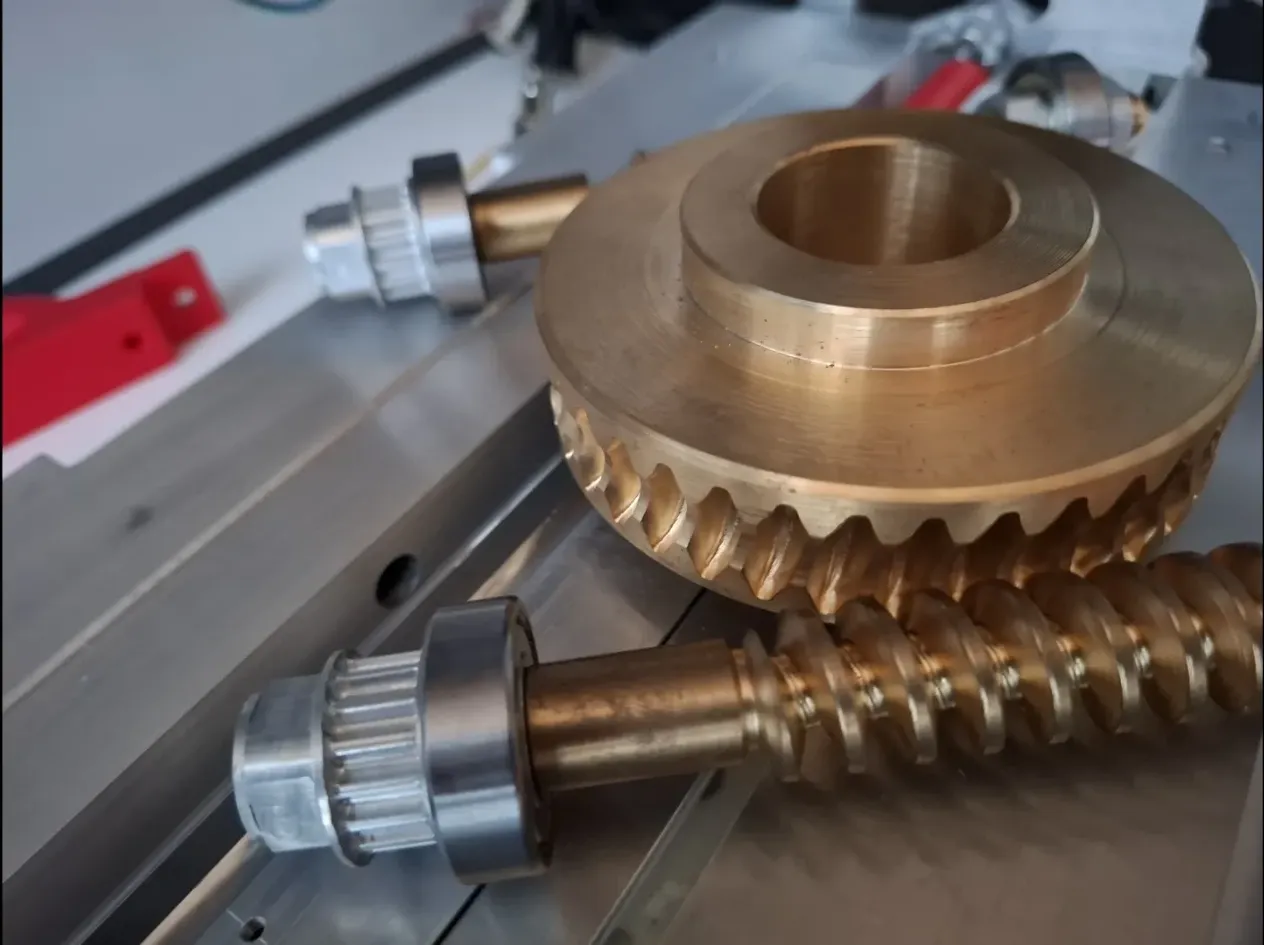

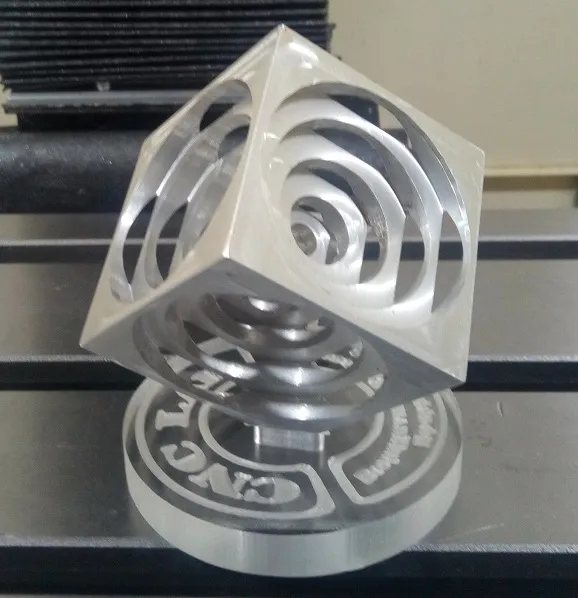

All of our machines are equipped with 4-axis capabilities,

making the construction of (almost every) geometry achievable.

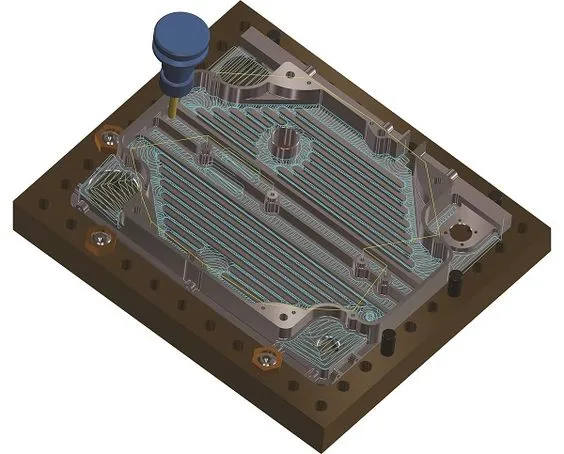

📌 Phase C: 🎯 Final phase - Realization

Now it's time for the machine to execute.

This is generally the least time-consuming phase of the process.

After placing the (previously prepared) stock material and defining the coordinate system,

the machine simply follows the instructions provided in the g-code program to produce the final geometry.

See some

of the finished products and prototypes from our portfolio.

(Click on image to enlarge)